Conveyor Engineering & Design

The IntelliTrak Process

Engineering Discovery Phase: System Specifications Defined

Factors that determine which IntelliTrak system would be most efficient for your application:

Size and weight of product being conveyed (see Load Capacity chart)

Available floor and ceiling space

Temperature/environment

Application process

Required throughput

Available options: lifts, shuttles, carriers, load bars, tool rail, lighting, conductor rail, anti-sway, spurs/deadheads, chording, over/under, incline/decline, carrier identification, accumulation

IntelliTrak Overhead Conveyor Load Capacity by Series

Engineering & Design of System

A custom IntelliTrak Overhead Conveyor System will be designed based on the above specifications and a thorough examination of current and future production processes and facility layout.

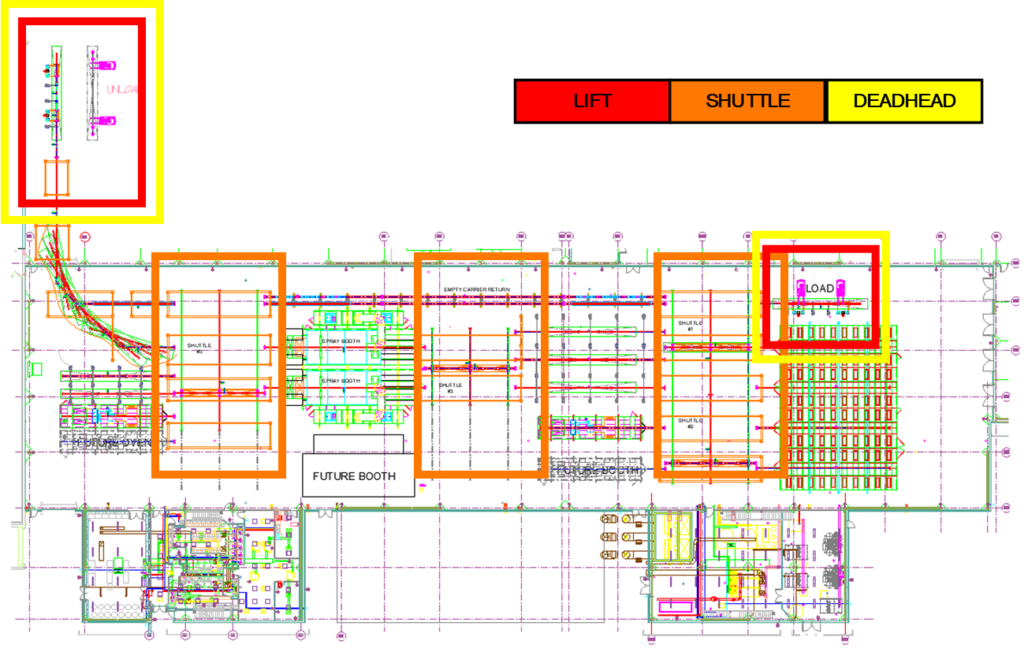

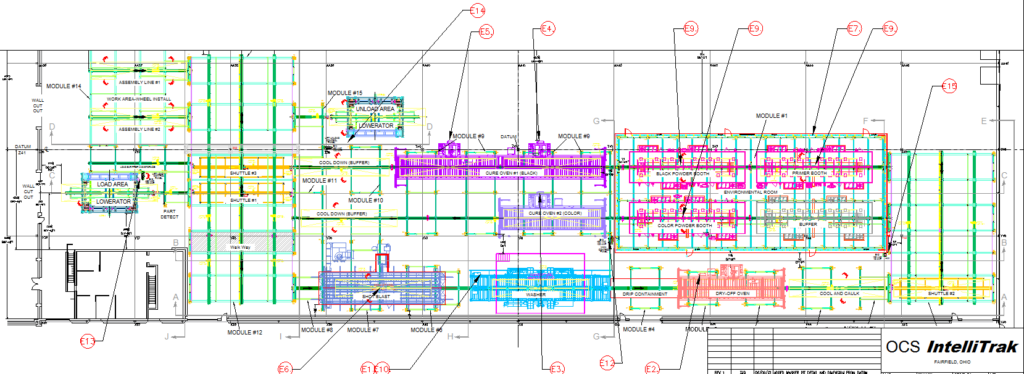

Example of CAD Drawing

Custom Conveyor Controls

IntelliTrak offers custom Controls Design, Panel Build and VPN Service by industry experts with over 20 years of experience, including:

- Complete system controls and automation design

- Standard and custom control panel design and assembly

- Drives, PLC and HMI programming

- Start-up services, training and support

Fabrication, Paint & Assembly

IntelliTrak Overhead Conveyor Systems are made in the USA by a highly-trained, experienced team, and state-of-the-art equipment, including:

- Manufacturing Engineers

- Fabricators

- Welders

- Paint Technicians

- Assemblers

Factory Acceptance Testing (if applicable)

A 50′ bay allows for FATs and run-offs, if applicable.

Installation

Highly-trained, professional staff will install your system or provide guidance should you choose to do your own installation.

Customer Support

By design, IntelliTrak conveyor systems require minimal maintenance. Informal instruction will be provided during installation, as well as a preventative maintenance schedule. Following this schedule will help keep your system in excellent condition for maximum productivity. When replacement parts are required, they can be ordered from our Fairfield, OH warehouse.